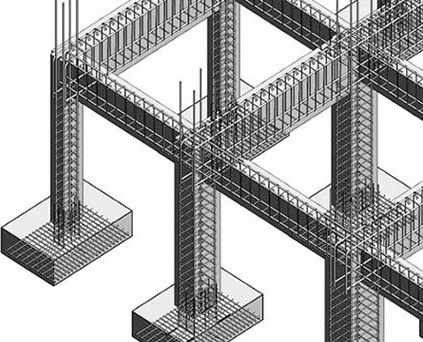

The basic rules for designing of columns are listed below:

1. The cross-sectional area of longitudinal steel in a column shall not be less than 0.8 and not more

than 6% of the gross-sectional area of the column.

In places where bars from a column below have to be lapped with those in the column to be

In places where bars from a column below have to be lapped with those in the column to be

designed, the maximum percentage of steel should not exceed 4%.

2. The diameter of longitudinal bars should not be less than 12 mm and should not be more than 50

2. The diameter of longitudinal bars should not be less than 12 mm and should not be more than 50

mm.

3. Round columns and columns having helical binders should have at least bars.

4. The minimum cover of concrete to the outside of longitudinal bars shall be 4 cm or the diameter of

3. Round columns and columns having helical binders should have at least bars.

4. The minimum cover of concrete to the outside of longitudinal bars shall be 4 cm or the diameter of

the bar whichever is greater. In case where the maximum dimension of a column does not exceed

20 cm and the diameter of the longitudinal bars does not exceed 12 mm, the cover of 2.5 cm may

be used.

5. Where it is necessary to splice the longitudinal bars, the bars shall overlap for a distance of not less

5. Where it is necessary to splice the longitudinal bars, the bars shall overlap for a distance of not less

than 24 times the diameter of the smallest bar.

6. The spacing of bars measured along the periphery of the column shall not exceed 300 mm.

6. The spacing of bars measured along the periphery of the column shall not exceed 300 mm.

B. TRANSVERSE REINFORCEMENT:

Transverse steel may be provided either in the form of lateral ties or helical bars (spiral).

1. The minimum diameter of the ties or helical reinforcement shall not less than 1/4th the diameter of

Transverse steel may be provided either in the form of lateral ties or helical bars (spiral).

1. The minimum diameter of the ties or helical reinforcement shall not less than 1/4th the diameter of

the largest longitudinal bars and in no case less than 5 mm.

2. The maximum diameter of the ties or helical steel should preferably be not more than 12 mm and

2. The maximum diameter of the ties or helical steel should preferably be not more than 12 mm and

25 mm respectively.

3. The pitch of the ties should not be more than the least of the following

a) Least lateral dimension of the column.

b) 16 times the diameter of the smallest longitudinal bar nearest to the compression face of the

3. The pitch of the ties should not be more than the least of the following

a) Least lateral dimension of the column.

b) 16 times the diameter of the smallest longitudinal bar nearest to the compression face of the

member.

c) 48 times the diameter of the tie.

4. Pitch of the helical reinforcement should not be more than least of the following:

a) 1/6th the diameter of the concrete core.

b) 75mm.

5. The least spacing of the lateral ties may be 150 mm and for spirals, the minimum pitch shall be 25

c) 48 times the diameter of the tie.

4. Pitch of the helical reinforcement should not be more than least of the following:

a) 1/6th the diameter of the concrete core.

b) 75mm.

5. The least spacing of the lateral ties may be 150 mm and for spirals, the minimum pitch shall be 25

mm or three times the diameter of the helical bars whichever is greater.